Email: obor@sdobor.com Tel: 0086-13205383163

Email: obor@sdobor.com Tel: 0086-13205383163

TPO Waterproof Membrane Factory

Product Description

OBOR TPO Waterproof Roofing Materials High Quality TPO Waterproof Membrane

TPO roll material combines ethylene propylene rubber and polypropylene using advanced polymerization technology, combining the excellent weather resistance and durability of ethylene propylene rubber with the weldability of polypropylene.

It is suitable for the waterproof layer of exposed or non exposed roofs in buildings, as well as the underground waterproofing of buildings that are prone to deformation. It is particularly suitable for the waterproofing of lightweight steel structure roofs and large concrete structure roofs. It is the preferred waterproof material for roofs of large industrial plants and public buildings.

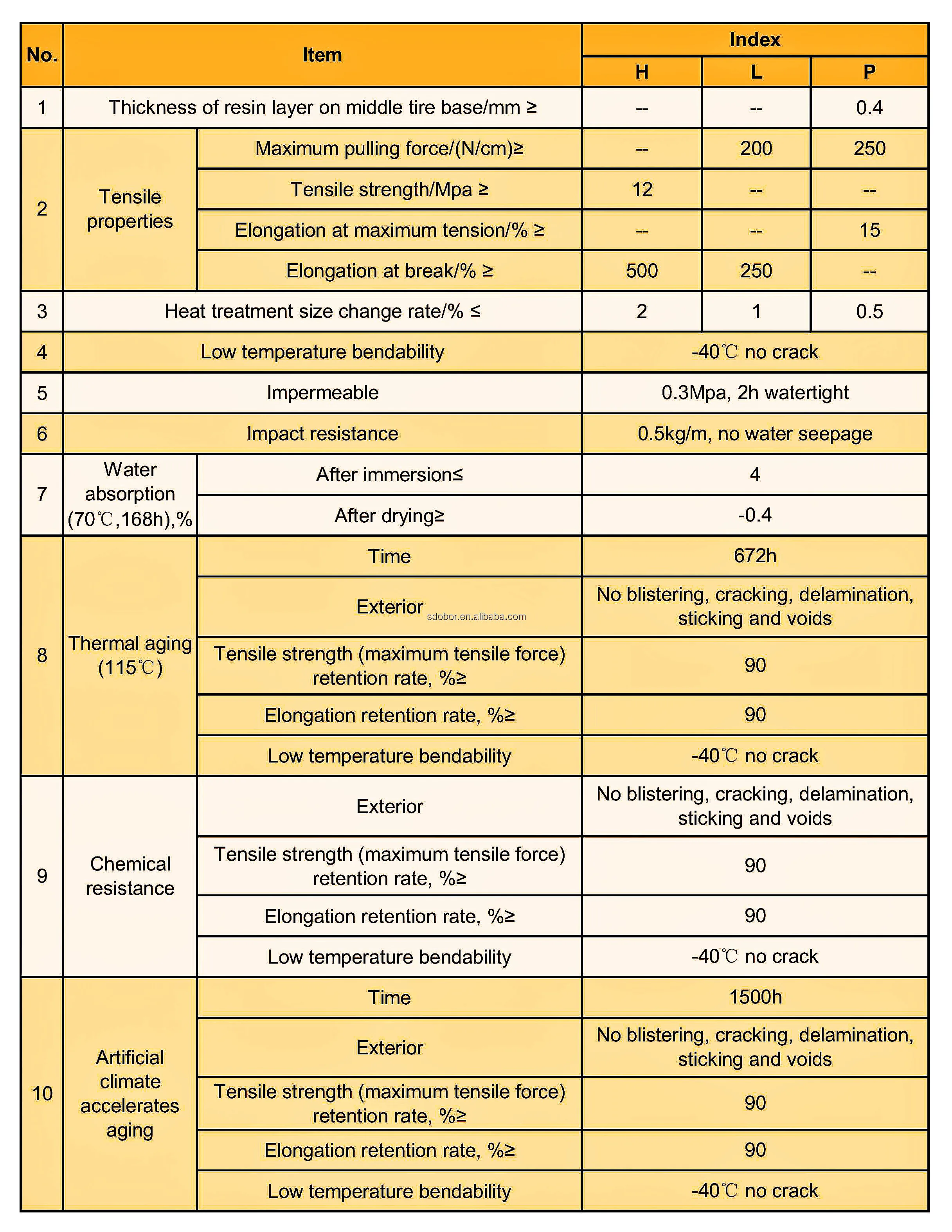

Divided by product categories: non-homogeneous composite membrane (code H), with fiber composite backing sheet (code L), fabric reinforced sheet (code P), Self-adhesive tpo waterproofing membranes.

Different installation options for FleeceBack TPO membrane

FleeceBack TPO membranes can be installed using various methods according to the specific needs of a roofing project. The primary

installation options include:

1. Fully Adhered System: This method involves applying adhesive to the roof deck or insulation and to the fleece backing of the membrane itself. After the adhesive is spread and allowed to become tacky, the FleeceBack TPO is rolled out onto the surface and pressed into place. The fleece backing provides a strong bond to the adhesive, creating a secure, watertight roofing system.

2. Mechanically Fastened System: In this approach, the membrane is attached to the roof deck using fasteners and stress plates. Although the fleece backing doesn't play a direct role in the mechanical attachment, it can provide an extra cushion and help protect the TPO membrane from potential damage from the fasteners.

3. Ballasted System: Ballasted installations involve laying the membrane loose and then holding it in place with a layer of ballast, such as river rock or pavers. The weight of the ballast keeps the membrane secure. While this method is not as common for FleeceBack membranes due to their adhesive-friendly nature, it can still be used in certain designs where appropriate.

4. Self-Adhered System: Some fleece-backed membranes come with a pre-applied adhesive layer protected by a release film. During installation, the release film is removed, and the membrane is rolled onto the substrate. This method can offer a cleaner and quicker installation process with fewer fumes compared to traditional adhesives.

5. Induction Welded System: With the induction welding method, specially designed plates are placed underneath the membrane, which are then fastened to the deck. An induction welding tool is then used to heat the membrane and the plate, causing the two to fuse together. This system allows for a high-performance bond and is good for roofs with high wind uplift requirements.

The choice of installation method for a FleeceBack TPO membrane depends on the building design, the local climate, the roof deck type, and other factors such as cost, labor efficiency, and desired performance characteristics. Each method has its benefits and considerations, and a professional roofing contractor can help determine the best option for a particular project.

Contact: Sophy

Phone: 0086-13205383163

Tel: 0086-13205383163

Email: obor@sdobor.com

Add: Economic Development Zone, Taian City, Shandong Province, China

We chat